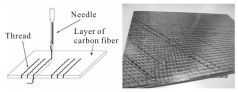

Carbon Fiber Reinforced Plastic (CFRP) is the most popular composite material in aircraft applications. Conventional CFRP is composed of many stacked carbon fiber layers and permeated resin. This realized recent light and strong aircraft structures. However, composite materials of stacked type have such a weak point that delamination may occur by impact load, which is one of the most serious problems in development of composite structures. In our study, CFRP is stitched by thread of Vectran to reinforce its interlayer strength, as shown in the figure. Such a stitching technology is expected to suppress delamination of composite laminates successfully.

Double Cantilever Beam (DCB) test which can evaluate interlaminar fracture toughness of stitched composites shows that our Vectran-stitched CFRP increases in fracture toughness significantly compared with Kevlar and Carbon stitched laminates.

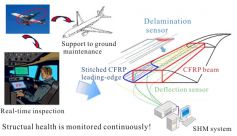

Development of structural health monitoring (SHM) system for damage detection is also important to establish the reliability of composite structures. We started the development of SHM system to evaluate the structural health of composite structures. Optical fiber sensors are embedded in dangerous portions of composite structures such as Ply-drop-off and Stringer-run-out. Our target is to develop optimum SHM on such critical portions.

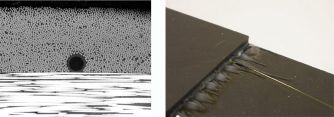

Optical fiber sensors can detect delamination, disbanding, bearing failure, etc. Photographs show an optical fiber sensor embedded in an adhesive layer between two CFRP plates.

Smart structures autonomously adapt its own properties based on the environmental fluctuation. More specifically, the structures take the form of a distributed control system where smart sensors/actuators are distributed within a structure. In this study, structural control systems that consist of smart sensors, smart actuators and smart controls are designed by modelling control targets as distributed parameter systems and by developing control theories based on physical properties of the models.

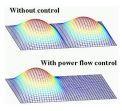

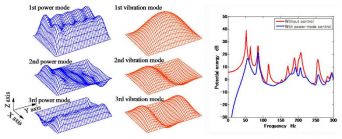

Based on wave or power flow analyses, a vibration-free state is generated in a certain area of a target structure. For instance, such a method enables a controller to manipulate the wave propagation, so that the vibration does not affect a structural region where critical cracks exist.

Attenuation of structural vibration does not always result in a reduction of noise radiation. In some cases, noise can be increased. To overcome this problem, this study presents the concept of an acoustical power mode which organically links vibration and acoustical fields. Amplitudes of the acoustical power modes can be measured by smart sensors, and their reduction ensures attenuation of noise radiation.